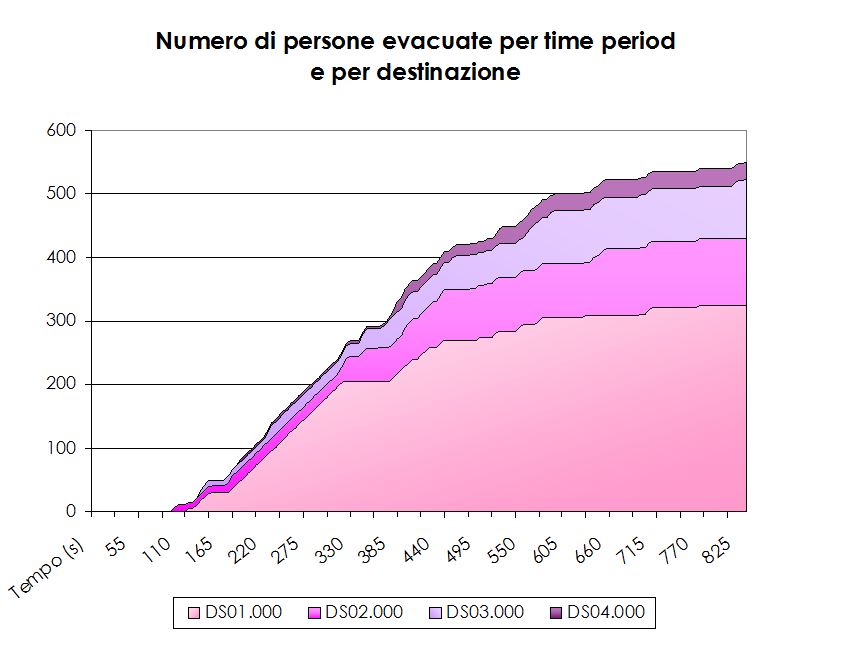

The objective of the study is to verify the suitability of the “exit system” in emergency conditions, by means of simulation supported by a suitable calculation code applied to suitably identified representative case studies of the industrial reality under examination.

The representative case studies on which to proceed to measure the suitability of the escape system are identified on the basis of the accident scenarios identified during the drafting of the Plant Safety Report and in consideration of situations of particular crowding of the refinery (with specific distribution of third party personnel operating on the site).

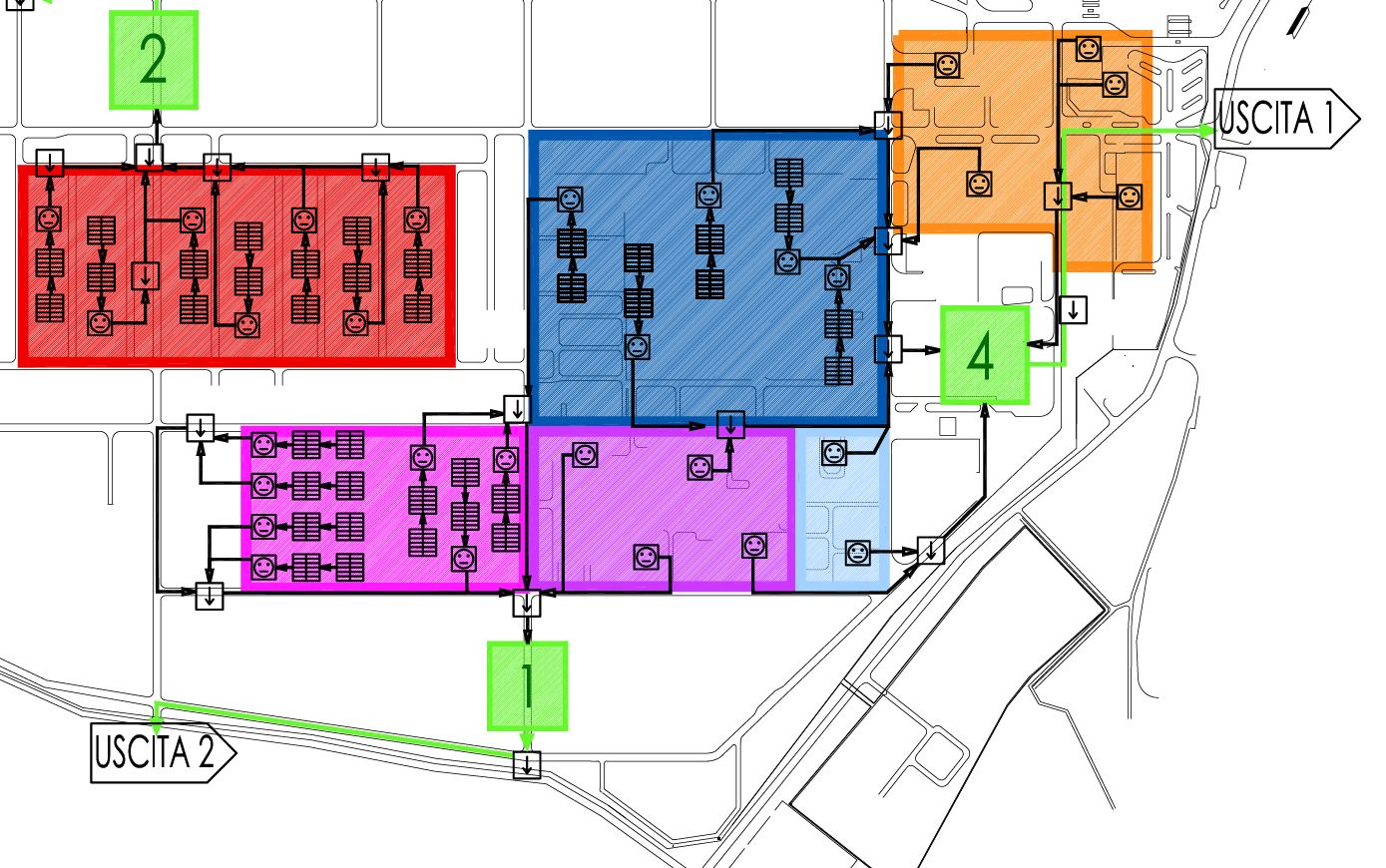

The verification is carried out by means of simulation, with a specific calculation code, of the performance of the entire system (escape routes, main escape manifolds, alternatives, etc.) in the configuration identified by the representative case study. The verification is intended as a tool to provide a complete picture of the efficiency and effectiveness of the evacuation plan envisaged by the Refinery.

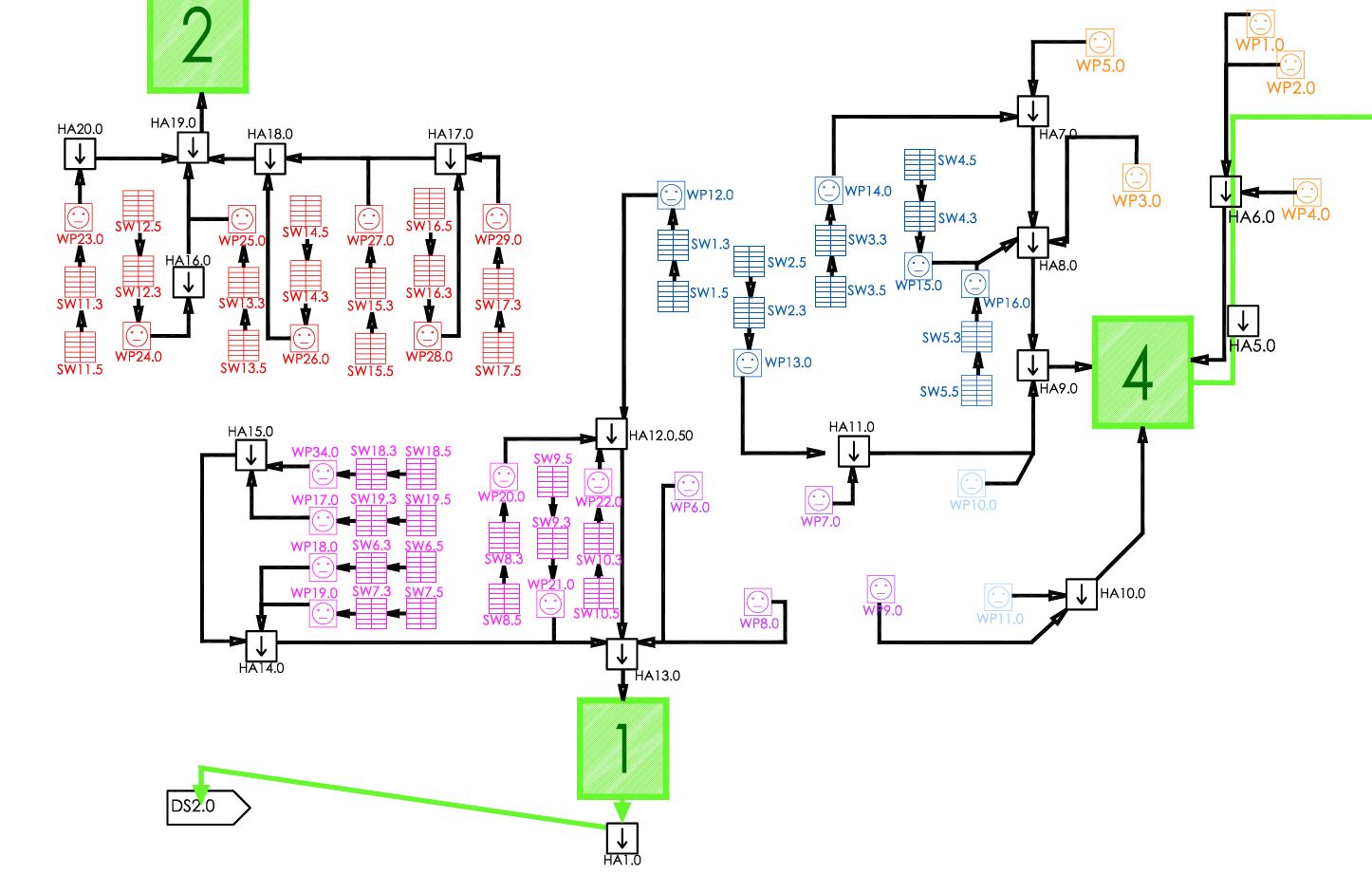

The simulation is carried out using the “EVACNET4” calculation code, a Microsoft© Windows© version of the original “EVACNET+” calculation code.

Case studies are prepared in order to identify representative situations for the site under examination: the purpose of each case study is to characterise the logic model input to the calculation code used for the simulation in terms of: number and location of personnel, capacity of escape routes and their length, influence on the escape system in terms of its unavailability or portions of it following the occurrence of any accident scenarios representative of the site highlighted by the risk analysis conducted, etc.

As part of the determination of the representative cases for the purpose of constructing the logical model as input to the calculation code, two specific situations were identified:

- base case (representing the typical operating situation of the Refinery), hereinafter referred to as CASE 1;

- case of “general shutdown and major maintenance”, hereinafter referred to as CASE 2.