As part of the process of continuous improvement of its processes, aimed in particular at the constant reduction of the environmental impacts of its installations and activities, the Company has expressed its intention to proceed with the identification of options to reduce the risks of major accidents connected with an uncontrolled reaction within process vessels.

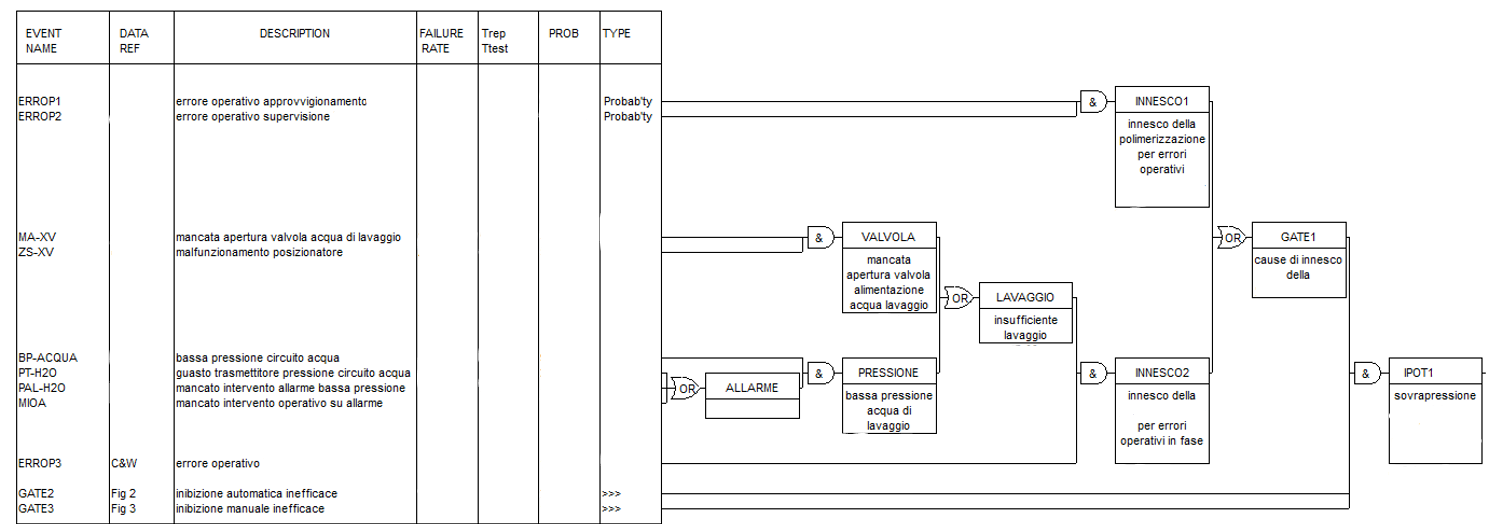

In particular, the Company’s interest was to assess the impact of the implementation of a new emergency inhibition system, on the frequency of occurrence of a specific accidental hypothesis, already previously identified with the HazOp / FTA technique

Where the introduction of the new inhibition system had not reduced the frequency to an acceptable level, the Company’s interest was moreover to identify possible options for further reduction.

The peculiarity of the activity lies in the use of two specific methodologies to define two specific aspects of the activity:

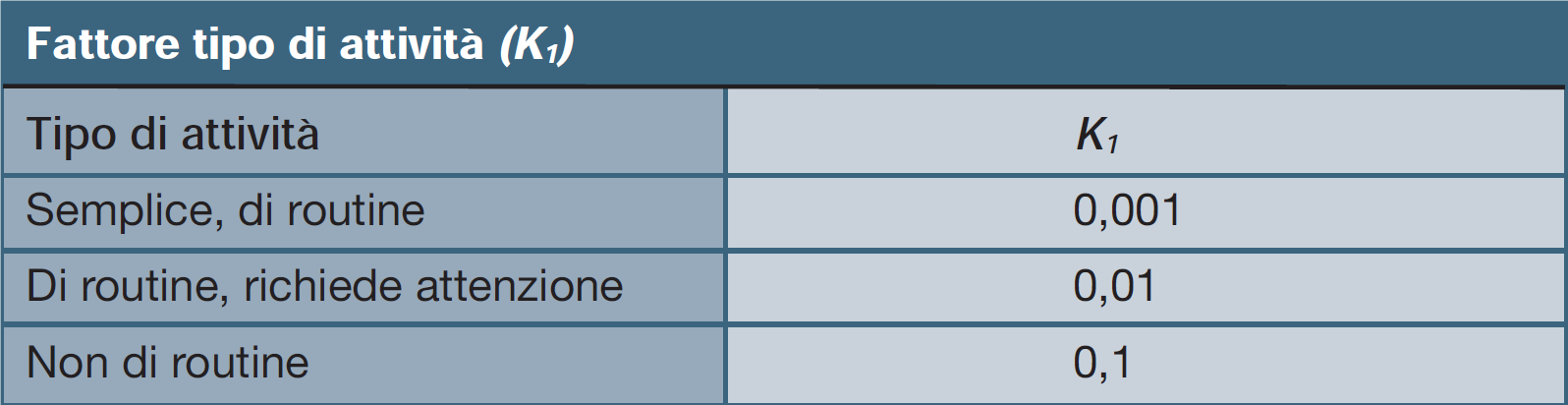

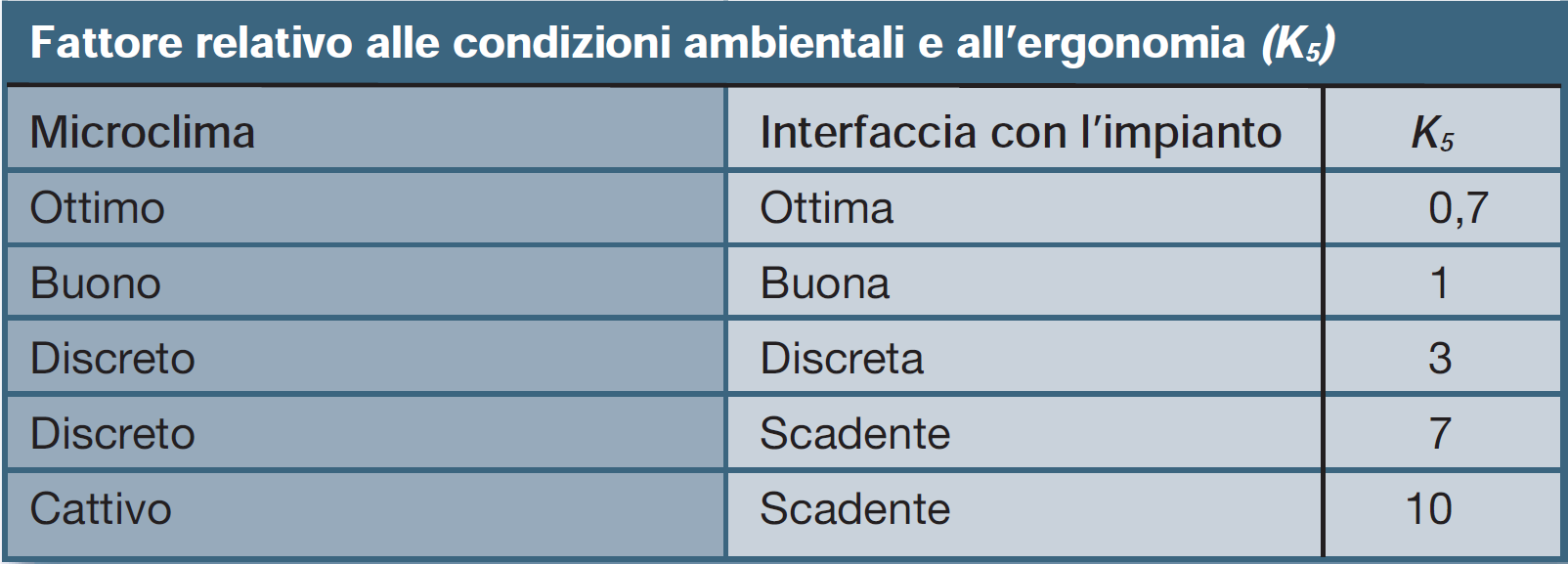

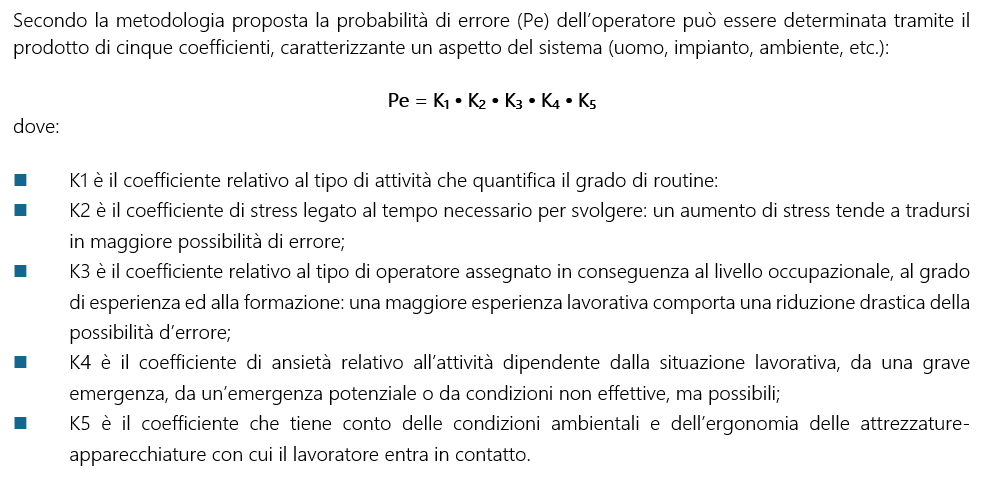

- the emergency injection system had two distinct modes: an automatic and a manual one. For the definition of human errors that could be committed in the actuation of the “manual” mode, the approach from the TESEO Methodology was used (ISPESL Prevenzione Oggi publication Vol. 5, No. 1/2, “The human factor in risk assessment: methodological comparison of techniques for analysing human reliability”) in view of the possibility of being used for global assessments of the probability of error of a task as a whole.

- In order to identify possible options for reducing the frequency of occurrence of the reference accidental hypothesis, sensitivity analysis was applied to the fault tree developed to include the new emergency injection system.

Sensitivity analysis is the study of the influence that a variation in the input data has on the final result of a model; the application of this methodology to fault trees allows a relative weighting factor to be determined for each primary event considered in the elaboration of the fault tree.

This factor is expressed by a numerical value, between 0 and 1, and represents the influence that this parameter has on the final result of the model.

According to the definition given in “System Reliability Theory – Hoyland, Rausand”, this measure represents the “conditional probability that at least one minimal cut set containing the ‘component’ is faulty (i.e. all events that make up the minimal cut set have occurred), given that the top event (incidental hypothesis) has occurred”.

The Logan Fault Tree® software from RM Consulting was used for the development of the Fault Tree Analysis.